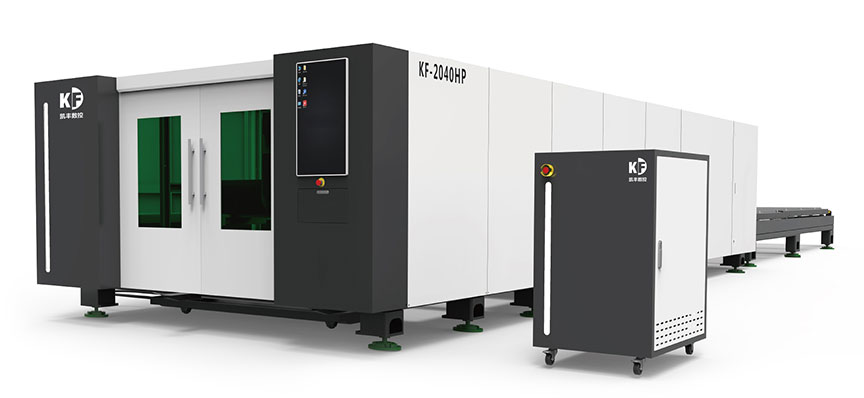

Components of Sheet Metal Cutting Machine

2023-10-18

A sheet metal cutting machine consists of several components that work together to cut sheet metal into the desired shapes and sizes. The specific components may vary depending on the type and design of the cutting machine. Here are some common components found in sheet metal cutting machines:

1. Frame : The frame provides the structure and support for the entire cutting machine. It is typically made of heavy-duty materials, such as steel, to ensure stability and rigidity during the cutting process.

2. Worktable : The worktable is where the sheet metal is placed for cutting. It may be a flat surface or have specialized features, such as a grid pattern or adjustable clamps, to hold the sheet metal securely in place.

3. Cutting Tool : The cutting tool is the main component responsible for cutting the sheet metal. The type of cutting tool varies depending on the cutting method, such as shearing blade for shearing machines, laser beam for laser cutting machines, or plasma torch for plasma cutting machines.

4. Drive System : The drive system powers the movement of the cutting tool along the sheet metal. It can be mechanical, hydraulic, or electric, depending on the type of cutting machine.

5. Control Panel : The control panel houses the controls and interface for operating the cutting machine. It may include buttons, switches, touchscreen displays, and other user-friendly features for setting parameters and managing the cutting process.

6. CNC System (if applicable) : In CNC cutting machines, a computer numerical control (CNC) system is used to program and control the cutting process. It interprets the design files and coordinates the movement of the cutting tool with high precision.

7. Coolant System (if applicable) : Some cutting machines, especially those using thermal cutting methods like plasma cutting or laser cutting, require a coolant system to dissipate heat and prevent the cutting tool from overheating.

8. Safety Features : Modern sheet metal cutting machines are equipped with various safety features, such as emergency stop buttons, safety shields, and interlocks, to ensure safe operation and protect operators from potential hazards.

9. Guiding System : The guiding system ensures precise and accurate movement of the cutting tool along the sheet metal. It may include rails, bearings, and linear motion systems.

10. Exhaust System (if applicable) : Certain cutting methods, such as laser cutting and plasma cutting, generate fumes and smoke. An exhaust system is used to remove these by-products from the cutting area for a cleaner and safer working environment.

11. Software and Control Algorithms (for CNC machines) : CNC cutting machines rely on specialized software and control algorithms to interpret design files, generate cutting paths, and optimize the cutting process for efficiency and accuracy.

These components work together to create a functional sheet metal cutting machine capable of accurately cutting and shaping sheet metal for various applications in industries such as manufacturing, construction, automotive, and aerospace.