Why Should You Consider a Hot Runner Mold for Your Production Line?

2025-07-25

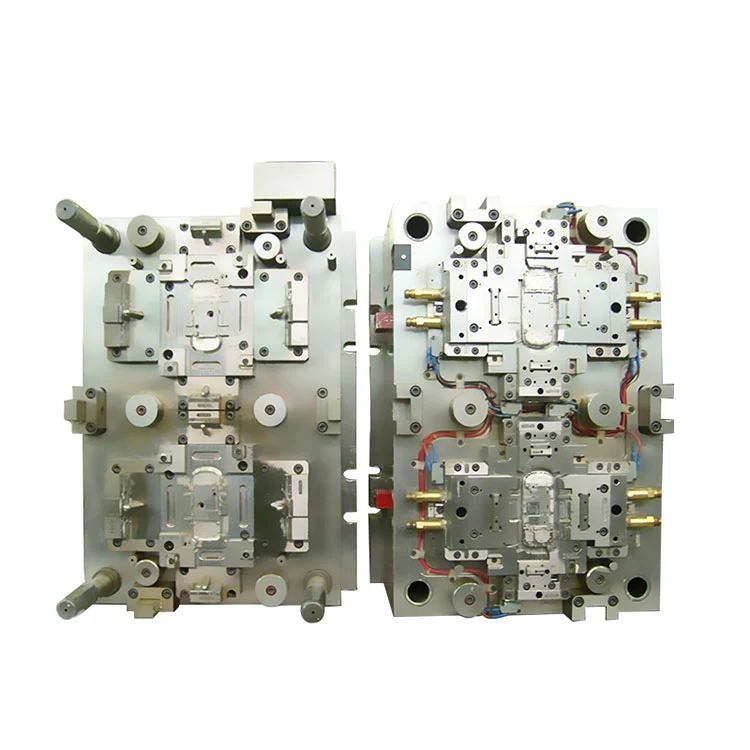

At Ningbo Moldor Plastic Co., Ltd., we’ve spent years working with manufacturers who need faster cycles, better product quality, and lower material costs. One tool that continues to prove its value in all these areas is the Hot Runner Mold. From my experience on the production floor to customer feedback across different industries, this system has become a reliable solution for modern injection molding.

The Hot Runner Mold works by keeping plastic in a molten state through a system of heated nozzles and channels. This design prevents the material from cooling and solidifying in the runner, which means it flows directly and evenly into the mold cavity. That helps cut down on waste, reduces the need for post-processing, and leads to more consistent results across each cycle.

In our daily work, we’ve seen how this system helps improve the appearance of injection gates and supports a smoother production rhythm. Because the plastic stays hot within the runner, we can shorten molding cycles and make better use of each machine’s capacity. This not only saves time but also helps control energy and raw material use.

What stands out to me most about the Hot Runner Mold is how it supports product consistency. It improves surface finishes, reduces warping, and makes it easier to mold parts that would be difficult with a cold runner system. Even when working with materials that are sensitive or prone to shrinkage, the results are more predictable.

We’ve designed our Hot Runner Mold to match the needs of real-world production—not just in theory, but in practice. Our team builds each mold with attention to temperature balance and channel layout, ensuring long-term reliability and performance. Whether the goal is to improve mechanical strength or reduce part deformation, this system is a practical way forward.

If you’re looking for a mold solution that helps reduce waste and raise product quality without complicating your workflow, I encourage you to learn more about what our Hot Runner Mold can do. Reach out to us at [email protected], and let’s talk about how we can support your next project.