What are the advantages of using blind flanges

2023-11-04

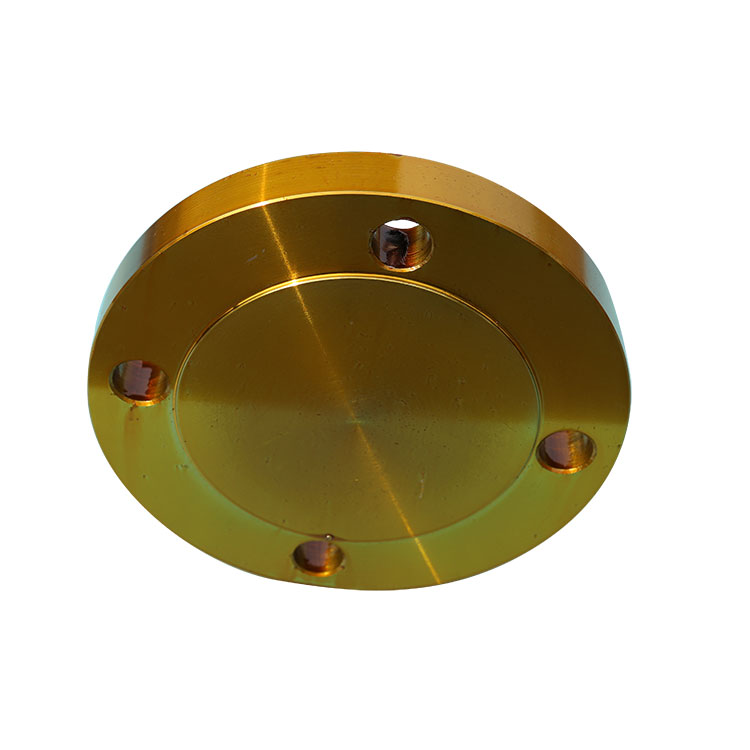

Blind flanges offer several advantages when used in piping systems, making them a valuable component for a variety of applications. Some of the key advantages of using blind flanges include:

1. Sealing and Closure: Blind flanges provide a secure and effective means of sealing off the end of a pipe or vessel, preventing the flow of fluid, gas, or other substances. This is particularly useful for isolation, testing, or temporary closure.

2. Versatility: Blind flanges are versatile and can be used in a wide range of applications, including petrochemical, oil and gas, water treatment, and more. They can be used for temporary closures, isolation, or as future connection points.

3. Maintenance and Inspection: Blind flanges allow for easy access to the interior of a piping system for inspection, maintenance, cleaning, or testing purposes. They can be removed and reinstalled as needed, making them practical for routine maintenance activities.

4. Safety: Blind flanges can be crucial for safety by preventing the accidental release of hazardous or pressurized materials from the open end of a pipeline. They help maintain safe working conditions in industrial and chemical processes.

5. Pressure and Leak Testing: Blind flanges are commonly used during pressure testing and leak testing of pipelines and equipment. They provide a reliable closure point to assess the integrity of the system.

6. Future Expansion or Connections: Blind flanges can be used as connection points for future extensions or branches in the piping system. This can save time and resources when the system needs to be modified or expanded.

7. Flow Control and Isolation: Blind flanges with bleeder holes can be used to control the flow of materials or to isolate sections of a pipeline for maintenance or repair.

8. Corrosion Resistance: Blind flanges can be manufactured from materials with excellent corrosion resistance, making them suitable for use in corrosive environments.

9. Cost-Effective Solution: Blind flanges are often more cost-effective than other types of closure methods, especially when temporary or intermittent closures are required.

10. Reduction in Environmental Impact: By preventing leaks or spills in the event of equipment malfunction or maintenance, blind flanges can help reduce the environmental impact of industrial processes.

In summary, blind flanges are valuable components in piping systems due to their ability to seal, isolate, and provide easy access for maintenance and inspection. Their versatility and safety features make them a practical choice for a wide range of industrial and commercial applications.