Unveiling the Strengths: Key Physical Properties of SBR Rubber Compound for Manufacturing Processes

2024-06-24

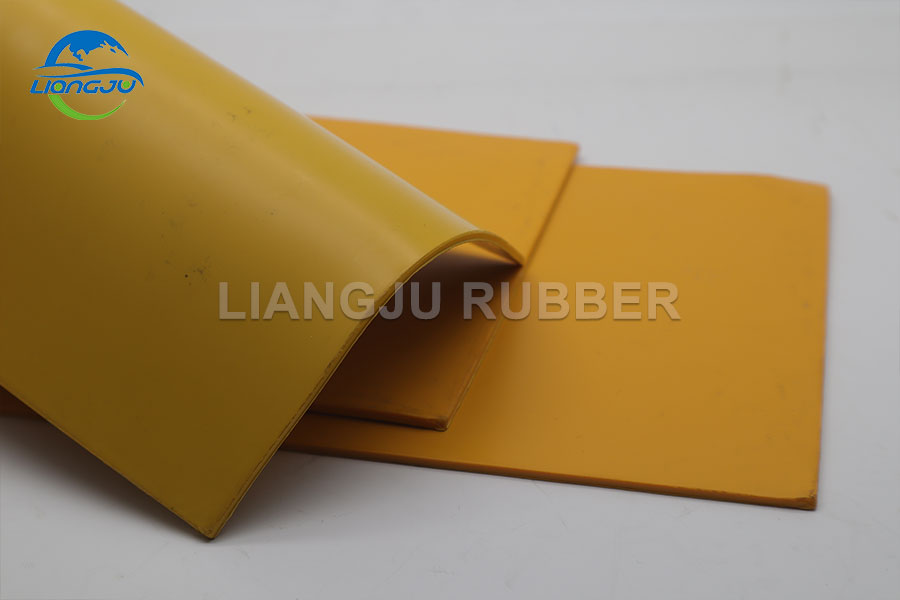

Styrene-Butadiene Rubber (SBR) is one of the most widely used synthetic rubber compounds, known for its versatility and reliability across numerous manufacturing processes. The unique blend of styrene and butadiene provides SBR with specific physical properties that make it an ideal choice for various industrial applications. In this blog, we will explore the key physical properties of SBR rubber compound that contribute to its widespread use in manufacturing.

1. Excellent Abrasion Resistance

Durability Under Stress: One of the standout features of SBR rubber compound is its exceptional abrasion resistance. This property ensures that products made from SBR can withstand harsh wear and tear, making it perfect for applications such as tire manufacturing, conveyor belts, and industrial hoses.

2. High Tensile Strength

Resistance to Breaking Under Tension: SBR exhibits high tensile strength, meaning it can endure significant stretching and pulling forces without breaking. This property is critical for products that require flexibility and resilience, such as automotive seals, gaskets, and various mechanical components.

3. Flexibility and Elasticity

Maintaining Shape and Functionality: SBR rubber compound maintains excellent flexibility and elasticity even at varying temperatures. This makes it suitable for dynamic applications where the material must bend, stretch, or compress without losing its original form, such as in footwear soles, sports equipment, and flexible tubing.

4. Good Aging and Weather Resistance

Long-Term Performance: SBR's resistance to aging and weather conditions is another key property. It performs well under exposure to ozone, UV radiation, and extreme temperatures, making it a reliable choice for outdoor applications like roofing membranes, playground surfaces, and weatherstripping.

5. Versatile Hardness Range

Customizable for Specific Needs: SBR rubber compound can be formulated to achieve various levels of hardness, from soft and pliable to hard and rigid. This versatility allows manufacturers to tailor the compound to specific applications, ensuring optimal performance in products like flooring materials, vibration dampers, and rubberized coatings.

6. Chemical Resistance

Withstanding Harsh Substances: SBR demonstrates good resistance to many chemicals, oils, and solvents. This property is particularly important for applications in the automotive, aerospace, and industrial sectors, where exposure to harsh chemicals is common. For example, SBR is used in fuel hoses, industrial seals, and protective coatings.

Conclusion

The key physical properties of SBR rubber compound—abrasion resistance, tensile strength, flexibility, aging resistance, hardness range, chemical resistance, cost-effectiveness, and ease of processing—collectively make it an indispensable material in the manufacturing industry. Whether in the production of tires, industrial hoses, footwear, or sealing solutions, SBR continues to demonstrate its value as a versatile and reliable material. As technology and industry demands evolve, SBR rubber compound is poised to remain a critical component in diverse manufacturing processes, contributing to the creation of durable, high-performance products.