Understanding the Automatic Brick Making Machine: A Revolution in Construction

2024-08-16

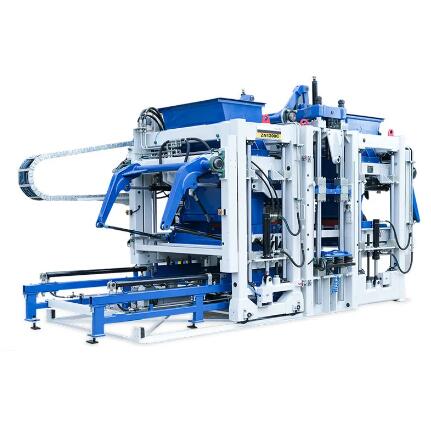

The construction industry has seen significant advancements over the years, with automation playing a pivotal role in streamlining processes and improving efficiency. One such innovation is the automatic brick making machine, a cutting-edge technology that has transformed the way bricks are produced. In this blog, we’ll explore what an automatic brick making machine is, how it works, and the benefits it offers to the construction industry.

What is an Automatic Brick Making Machine?

An automatic brick making machine is a highly efficient and sophisticated piece of equipment designed to produce bricks automatically with minimal human intervention. These machines can produce various types of bricks, including solid, hollow, interlocking, and paving bricks, using different materials such as cement, fly ash, sand, and concrete. The automation aspect significantly reduces labor costs and production time, making it a valuable asset for large-scale construction projects.

How Does the Automatic Brick Making Machine Work?

The operation of an automatic brick making machine involves several key processes, all of which are controlled by a centralized computer system:

1. Material Feeding:

Raw materials, such as cement, sand, fly ash, and water, are fed into the machine’s hopper. The machine automatically measures and mixes these materials in precise proportions to ensure consistency in the brick’s quality.

2. Molding:

The mixed material is then transferred to the molding section, where it is compressed under high pressure to form bricks. The molds can be customized to produce bricks of different shapes and sizes, depending on the project’s requirements.

3. Curing:

After molding, the bricks are transferred to a curing chamber where they are allowed to harden and gain strength. Some machines have an integrated curing system that uses steam or other methods to accelerate the curing process, ensuring that the bricks are ready for use in a shorter time.

4. Ejection and Stacking:

Once cured, the bricks are automatically ejected from the molds and stacked for further drying or packaging. This process is also automated, reducing the need for manual handling and ensuring that the bricks are stacked uniformly.

5. Quality Control:

Modern automatic brick making machines come equipped with quality control features that monitor the dimensions, density, and strength of each brick. Any defective bricks are automatically rejected, ensuring that only high-quality products reach the market.

Benefits of Using an Automatic Brick Making Machine

1. Increased Production Efficiency:

The automation of brick production significantly speeds up the manufacturing process, allowing for the production of thousands of bricks per day. This efficiency is crucial for meeting tight construction deadlines and reducing project costs.

2. Consistent Quality:

Automatic brick making machines are designed to produce bricks with consistent dimensions, strength, and quality. This consistency ensures that the bricks meet industry standards and are suitable for various construction applications.

3. Cost-Effective:

While the initial investment in an automatic brick making machine may be higher than traditional methods, the long-term savings in labor, material wastage, and production time make it a cost-effective solution for large-scale construction projects.

4. Eco-Friendly:

Many automatic brick making machines are designed to use environmentally friendly materials, such as fly ash and slag, which are by-products of industrial processes. This not only reduces the carbon footprint of the brick-making process but also contributes to waste management efforts.

5. Versatility:

These machines can produce a wide range of brick types and sizes, making them versatile enough to meet the diverse needs of different construction projects. Whether you need bricks for building walls, pavements, or decorative purposes, an automatic brick making machine can cater to your requirements.

Conclusion

The automatic brick making machine represents a significant leap forward in construction technology. By automating the brick production process, these machines offer numerous benefits, including increased efficiency, consistent quality, and cost savings. As the construction industry continues to evolve, the adoption of such advanced technologies will be crucial in meeting the demands of modern infrastructure development.