Understanding the Applications and Benefits of Tantalum Carbide Coating Rings

2025-01-15

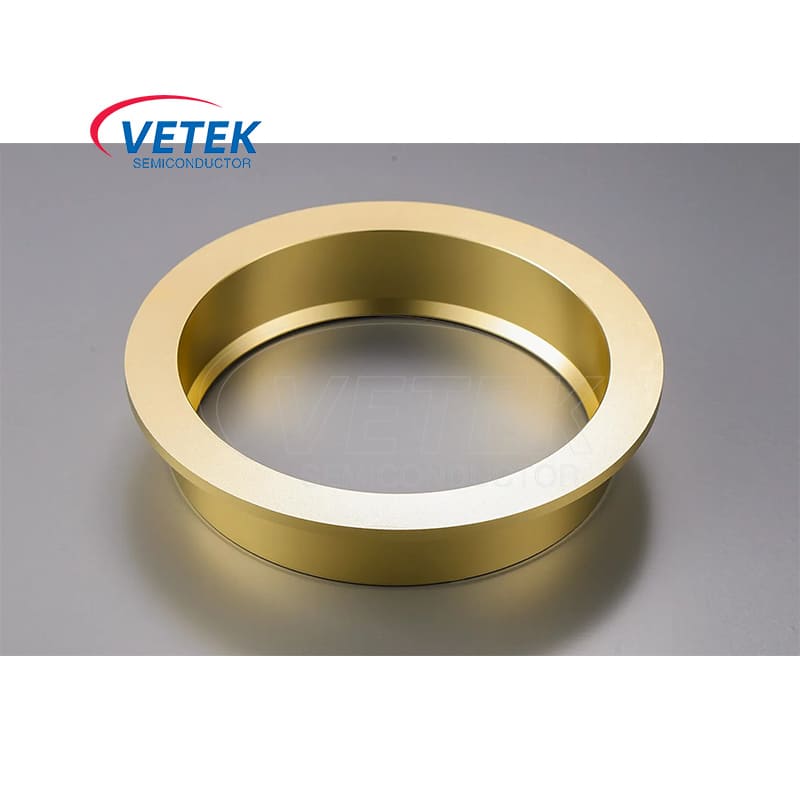

Tantalum carbide (TaC) coating rings are gaining prominence in industries that demand exceptional durability and resistance to extreme conditions. Known for their high hardness and exceptional thermal stability, these coatings are applied to various components to enhance performance and longevity. In this blog, we’ll explore the applications and advantages of tantalum carbide coating rings.

1. What is Tantalum Carbide?

Tantalum carbide is a refractory ceramic material made of tantalum and carbon. It is widely recognized for:

- High Hardness: Comparable to diamond in certain aspects.

- Thermal Stability: Maintains properties at temperatures exceeding 4,000°F (2,200°C).

- Corrosion Resistance: Excellent resistance to oxidation and chemical attack.

These properties make tantalum carbide an ideal material for coatings in demanding environments.

2. Applications of Tantalum Carbide Coating Rings

Tantalum carbide coating rings are used across a variety of industries:

- Aerospace Industry:

Components like nozzles and turbine rings benefit from the high-temperature resistance of TaC coatings, ensuring reliable performance in extreme heat.

- Semiconductor Manufacturing:

In semiconductor fabrication, where precision and contamination resistance are critical, tantalum carbide-coated rings protect tools and chambers from chemical degradation.

- Chemical Processing:

TaC-coated rings are used in environments with strong acids or alkalis, ensuring longevity in corrosive settings.

- Cutting and Tooling:

Tantalum carbide increases the lifespan and efficiency of cutting tools by reducing wear and maintaining sharpness over extended periods.

3. Advantages of Tantalum Carbide Coating Rings

- Durability: Provides a robust protective layer that minimizes wear and tear.

- Heat Resistance: Performs reliably under high-temperature conditions, making it ideal for demanding applications.

- Corrosion Protection: Ensures long-term resistance to harsh chemicals and oxidation.

- Improved Performance: Enhances operational efficiency by reducing downtime and maintenance requirements.

4. Key Industries Benefiting from TaC Coating Rings

Industries that operate in extreme conditions have found tantalum carbide coatings indispensable:

- Energy Sector: For equipment exposed to intense heat and corrosive environments.

- Medical Field: Precision instruments benefit from the biocompatibility and durability of TaC coatings.

- Industrial Manufacturing: Ensures the durability of high-wear components in heavy machinery.

Tantalum carbide coating rings are an exceptional solution for industries that require components to withstand high temperatures, abrasive forces, and corrosive environments. With applications ranging from aerospace to chemical processing, these coatings enhance performance and reduce operational costs. Understanding their properties and benefits is the first step toward integrating them into advanced systems.