Sustaining Precision: The Art of Maintenance for Longevity in Die Making Operations

2023-11-30

Introduction:

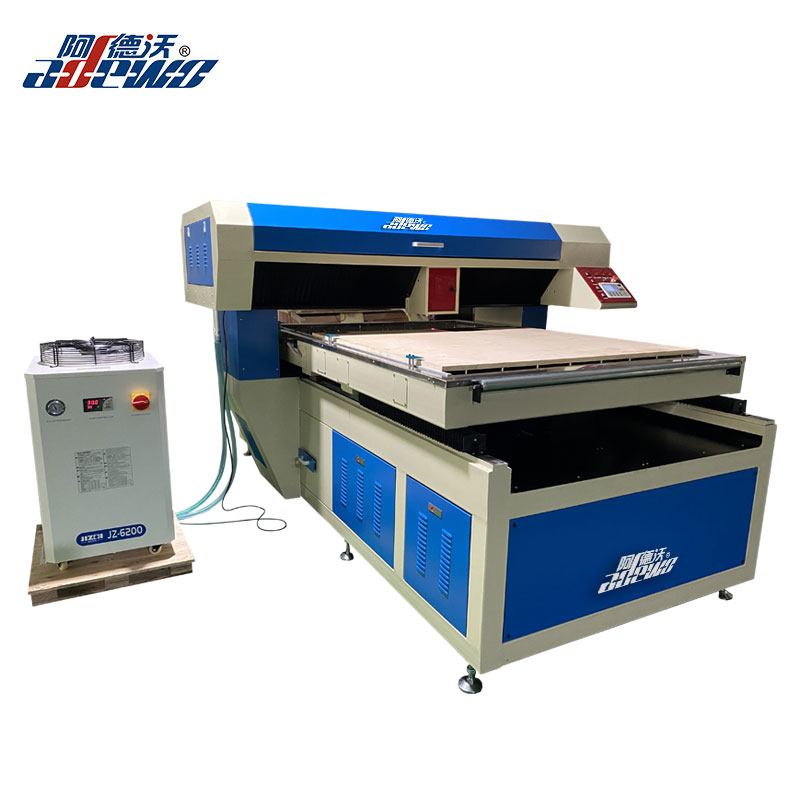

In the intricate dance of precision that defines the world of die making, the longevity and optimal performance of machinery are pivotal. Our Die Making Laser Cutting Machine isn't just a tool; it's a meticulously crafted instrument designed for sustained excellence. In this blog, we unravel the importance of maintenance and servicing in extending the life and optimizing the performance of our machine in die-making operations.

1. Regular Inspection Protocols:

The first step towards ensuring longevity is a commitment to regular inspections. Our machine is designed with accessible components, facilitating routine checks that allow operators to identify and address potential issues before they escalate. This proactive approach helps maintain optimal performance over the long term.

2. Lubrication and Wear Prevention:

Precision machinery relies on smooth movements, and lubrication is the lifeblood that keeps these movements seamless. Our Die Making Laser Cutting Machine features a comprehensive lubrication system, with clear guidelines on lubrication intervals. This preventive measure minimizes wear and tear, contributing to the extended life of critical components.

3. Scheduled Maintenance Plans:

To simplify the maintenance process for operators, our company provides scheduled maintenance plans. These plans outline the recommended maintenance tasks, intervals, and procedures, ensuring that operators have a clear roadmap to follow for optimal machine care.

4. Predictive Maintenance Technologies:

Embracing the latest in technology, our machine incorporates predictive maintenance features. Advanced sensors and monitoring systems track the machine's performance in real-time, providing insights into potential issues before they impact operations. This predictive capability empowers operators to take preemptive measures, minimizing downtime and extending the lifespan of the machine.

5. Comprehensive Training Programs:

An integral aspect of maintenance is the knowledge and skill of the operators. Our company offers comprehensive training programs that cover not only the operation of the machine but also best practices for maintenance. Well-trained operators are better equipped to perform routine checks, identify issues, and conduct basic maintenance tasks, contributing to overall machine longevity.

6. Efficient Cooling Systems:

Heat is a natural byproduct of high-performance machinery. Our laser cutting machine features efficient cooling systems that regulate temperature, preventing overheating and ensuring consistent performance. A well-regulated temperature environment is a key factor in enhancing the durability of sensitive components.

7. Accessible and Replaceable Parts:

In the spirit of user-friendly maintenance, our machine is designed with accessibility in mind. Critical components are easily accessible, facilitating swift replacement if needed. This design philosophy reduces downtime during maintenance tasks and contributes to the overall ease of servicing.

8. Collaborative Support and Remote Assistance:

Our commitment to customer satisfaction extends beyond the sale of the machine. We offer collaborative support and remote assistance to operators facing maintenance challenges. This support network ensures that operators have access to expert guidance, troubleshooting assistance, and the necessary resources to address maintenance issues promptly.

Conclusion:

In the world of die making, where precision is the currency of excellence, the longevity and optimal performance of machinery are non-negotiable. Our Die Making Laser Cutting Machine embodies a commitment to longevity through meticulous maintenance practices. From regular inspections and lubrication to predictive maintenance technologies, our approach is holistic, ensuring that operators can depend on the machine for sustained precision over its extended lifespan. In the delicate art of die making, our machine is not just a tool; it's a partner in craftsmanship that stands the test of time.