Key Considerations When Implementing a Plastic Central Water Cooling System

2024-11-15

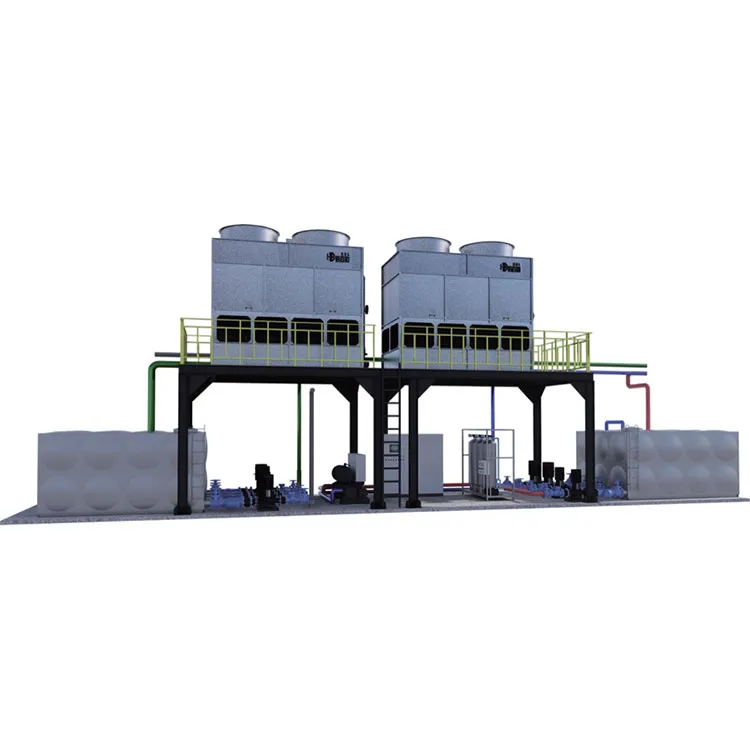

The Plastic Central Water Cooling System is an innovative and reliable solution for managing heat in industrial and commercial applications. Whether you are designing a new cooling system or upgrading an existing one, there are several key considerations to keep in mind to ensure successful implementation and optimal performance. In this blog, we will dive deeper into the critical factors that impact the effectiveness of a plastic-based water cooling system and how to maximize its benefits.

1. Choosing the Right Plastic Material

The choice of plastic material is one of the most important factors in designing a plastic central water cooling system. Different plastics offer distinct advantages, so understanding the specific requirements of your application will help you select the most appropriate material. Some common materials used in these systems include:

- Polypropylene (PP): Known for its excellent chemical resistance and durability, PP is ideal for industrial applications where the cooling system may come into contact with aggressive chemicals or contaminants. It is also heat-resistant and performs well in higher temperature environments.

- Polyvinyl Chloride (PVC): PVC is a widely used plastic due to its cost-effectiveness and ease of use. It is suitable for most applications that do not require extreme temperature resistance but still need good strength and corrosion resistance.

- High-Density Polyethylene (HDPE): HDPE is another popular choice for cooling systems because of its flexibility, impact resistance, and strength. It also offers excellent resistance to corrosion and UV degradation, making it a good choice for outdoor or exposed installations.

- Reinforced Plastic Composites: These materials combine plastics with fibers or resins to improve strength and performance under high pressures. They are often used in high-performance cooling systems where both strength and flexibility are required.

The selected material should align with the system’s operating environment, including temperature range, chemical exposure, and durability requirements.

2. System Design and Sizing

The design and sizing of a plastic central water cooling system play a crucial role in ensuring it operates efficiently. Key factors to consider when designing the system include:

- Flow Rate: The cooling capacity of the system depends largely on the flow rate of the water being circulated. It's essential to calculate the required flow rate based on the heat load and temperature differential between the coolant and the equipment being cooled.

- Pipe Diameter and Length: The diameter and length of the pipes affect the system’s pressure drop and flow resistance. The larger the diameter of the pipes, the lower the resistance and the better the flow. However, this must be balanced with the cost of materials and installation.

- Heat Exchange Efficiency: Incorporating an efficient heat exchanger into the system design is essential for transferring heat from the water to the ambient air. The design of the heat exchanger should ensure maximum heat transfer and minimize resistance to the flow of coolant.

- Pump Selection: The pumps used to circulate the coolant need to be sized correctly to ensure adequate water flow and pressure throughout the system. Underpowered pumps will result in insufficient cooling, while overpowered pumps may lead to energy inefficiencies and excessive wear.

3. System Maintenance and Monitoring

While plastic central water cooling systems are known for their low maintenance requirements, periodic checks and maintenance are still necessary to ensure optimal performance. Regularly monitoring key aspects such as water quality, flow rates, and pressure levels can help identify and address potential issues before they escalate.

- Water Treatment: Depending on the water source, it may be necessary to treat the water to prevent the buildup of scale or algae. This can include adding anti-scaling agents, biocides, or filters to remove particulates and impurities.

- Leak Detection: Plastic components are generally more resistant to leaks than metal systems, but it’s still important to regularly check for signs of water leakage in the system. Leak detection sensors can be installed to alert operators to any issues in real-time.

- System Inspections: Routine inspections of the cooling tower, heat exchangers, and piping can help ensure that no components are becoming clogged, damaged, or corroded over time. Replacing worn or damaged parts promptly will help extend the life of the system.

4. Environmental and Energy Considerations

Plastic central water cooling systems are generally more energy-efficient and eco-friendly compared to traditional air-cooled systems. However, optimizing energy usage and ensuring minimal environmental impact are key goals for modern cooling systems.

- Energy Efficiency: The design should focus on maximizing cooling efficiency while minimizing energy consumption. Choosing energy-efficient pumps, variable-speed drives, and ensuring proper system insulation can help reduce energy costs.

- Sustainable Materials: Consider using recycled plastics or biodegradable materials when possible to reduce the environmental footprint of the system. Additionally, ensure that the water used in the system is properly treated and disposed of, avoiding contamination of local water sources.

Implementing a Plastic Central Water Cooling System requires careful consideration of materials, design, maintenance, and energy efficiency. By selecting the right materials, optimizing the system’s design, and conducting regular maintenance, businesses can ensure that their cooling system operates efficiently, cost-effectively, and with minimal environmental impact. Whether in industrial plants, commercial buildings, or data centers, a properly designed and well-maintained plastic cooling system can provide reliable, long-lasting performance, helping to maintain optimal temperatures and reduce downtime.