How to Choose the Right Plate Brake Tester: Key Components to Consider

2024-10-29

When it comes to ensuring vehicle safety, having the right equipment is paramount. A plate brake tester is a crucial tool for assessing braking performance. However, with various models and specifications available, how do you choose the right one? Understanding the key components of a plate brake tester will help guide your decision. In this blog, we’ll discuss what to look for when selecting a plate brake tester based on its components.

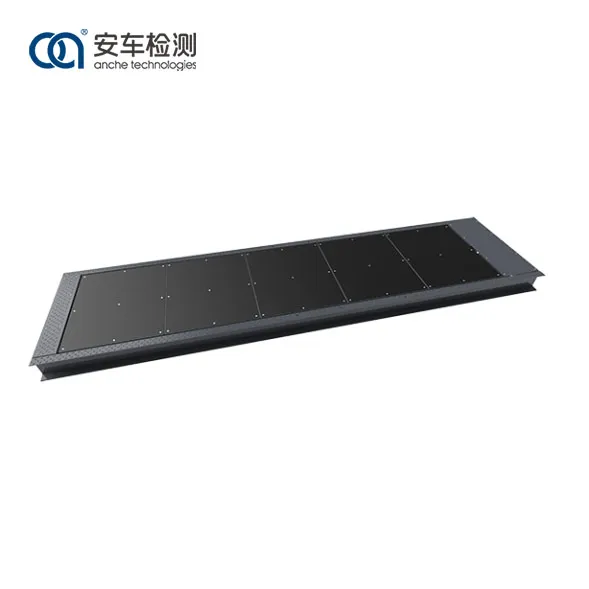

1. Testing Plate Size and Material

The size and material of the testing plates are fundamental considerations. Ensure that the plates are large enough to accommodate various vehicle types, from passenger cars to heavy-duty trucks. Additionally, plates made from durable materials can withstand repeated use and provide accurate testing results over time.

2. Quality of Load Cells

The load cells are essential for measuring braking force accurately. Look for testers with high-quality load cells that offer precision and reliability. Check the specifications to ensure that the load cells have a suitable capacity for the vehicles you plan to test. Additionally, consider models that allow for easy calibration of load cells to maintain accuracy.

3. Control Unit Features

The control unit is a critical aspect of a plate brake tester. Choose a model with an intuitive interface that simplifies operation and data interpretation. Look for features like:

- Real-Time Data Display: A clear, digital display that shows measurements during testing.

- Adjustable Settings: Options to customize parameters based on vehicle types and testing conditions.

4. Data Recording and Reporting Capabilities

An effective data recording system is essential for tracking vehicle performance over time. Choose a plate brake tester that offers robust data storage and reporting features. This will allow you to generate detailed reports for fleet management or regulatory compliance, enhancing the value of your testing equipment.

5. Safety Features

Safety should always be a top priority. When selecting a plate brake tester, ensure it is equipped with adequate safety features such as:

- Emergency Stop Button: This is essential for quickly halting testing in case of an emergency.

- Overload Protection: Ensures that the tester can handle the maximum expected braking force without damage.

6. Maintenance and Support

Finally, consider the availability of maintenance and technical support from the manufacturer. A good warranty and access to customer service can save time and resources in case of issues with the equipment. Regular maintenance is crucial for keeping the plate brake tester in optimal working condition.

Choosing the right plate brake tester involves careful consideration of its key components, including testing plate size and material, load cell quality, control unit features, data recording capabilities, safety features, and maintenance support. By focusing on these aspects, you can ensure that you invest in a reliable and efficient plate brake tester that meets your needs and upholds safety standards. In the automotive industry, having the right tools is essential for delivering high-quality service and ensuring the safety of all vehicles on the road.