Ensuring Excellence: Quality Control Measures in Edge Banding Cells

2024-03-15

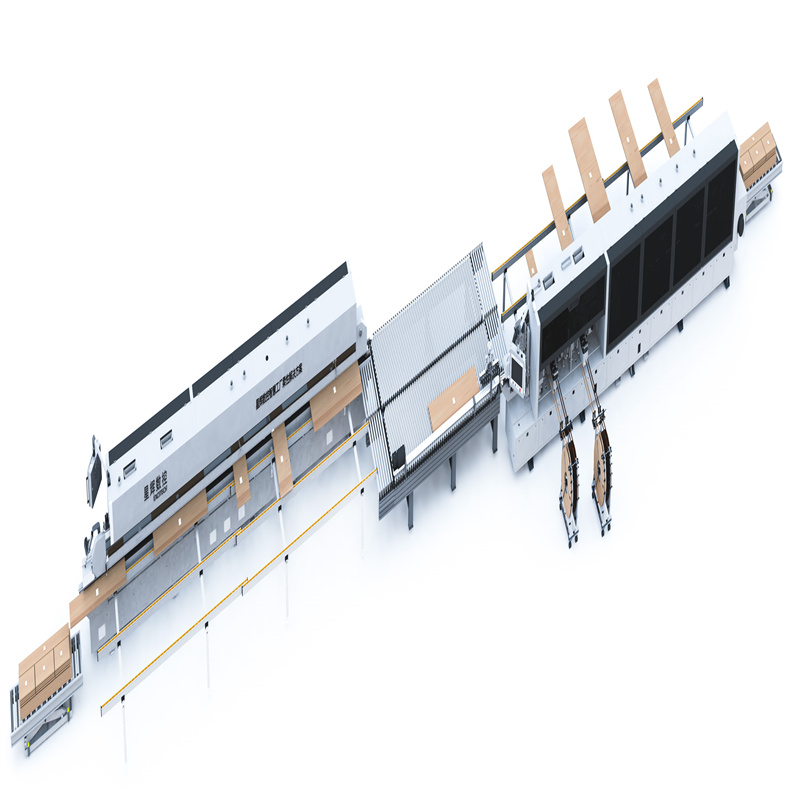

In the realm of manufacturing, quality is non-negotiable. Whether producing furniture, cabinetry, or other wood-based products, maintaining high standards of quality is essential for customer satisfaction and brand reputation. Edge banding cells play a crucial role in this process, applying edge banding material to workpieces to create a finished product with a seamless appearance and durable finish. To ensure the production of high-quality finished products, edge banding cells incorporate a range of sophisticated quality control measures. In this blog, we'll explore these measures and their importance in delivering excellence in manufacturing.

1. Automated Inspection Systems:

One of the key quality control measures implemented within edge banding cells is the use of automated inspection systems. These systems utilize advanced sensors, cameras, and vision algorithms to inspect workpieces and edge banding material in real-time. They can detect defects such as misalignment, uneven edges, bubbles, or delamination, ensuring that only high-quality workpieces proceed to the next stage of production.

2. Dimensional Accuracy Checks:

Dimensional accuracy is critical in edge banding operations to ensure a seamless fit and finish. Edge banding cells incorporate dimensional accuracy checks to verify that workpieces and edge banding material meet specified dimensions and tolerances. This may involve measuring the length, width, and thickness of workpieces, as well as the width and thickness of edge banding material, using precision sensors and measurement tools.

3. Adhesive Application Monitoring:

The proper application of adhesive is essential for ensuring the adhesion and durability of edge banding material. Edge banding cells monitor adhesive application processes to ensure uniform coverage and proper bonding. Sensors and monitoring systems track adhesive flow rates, temperatures, and pressures, alerting operators to any deviations from optimal conditions that may affect the quality of the finished product.

4. Edge Banding Alignment Verification:

Achieving precise alignment between workpieces and edge banding material is crucial for creating a seamless appearance and preventing unsightly gaps or overlaps. Edge banding cells incorporate alignment verification systems to ensure that edge banding material is applied with precision and consistency. These systems use sensors and vision algorithms to detect deviations from specified alignment tolerances and make automatic adjustments to maintain alignment accuracy.

5. Trimming and Finishing Quality Checks:

The trimming and finishing processes are critical for achieving a clean and polished edge on the finished product. Edge banding cells perform quality checks on trimmed edges to ensure smoothness, uniformity, and consistency. This may involve visual inspections, tactile evaluations, or automated measurements to verify that trimmed edges meet specified quality standards.

6. Continuous Process Monitoring and Improvement:

Quality control is an ongoing process in edge banding cells, with continuous monitoring and improvement initiatives in place to optimize production quality. Operators and quality control personnel closely monitor production metrics, analyze performance data, and identify opportunities for improvement. By implementing corrective actions and process refinements, edge banding cells strive for continuous quality improvement and excellence in manufacturing.

In conclusion, edge banding cells incorporate a range of quality control measures to ensure the production of high-quality finished products. From automated inspection systems and dimensional accuracy checks to adhesive application monitoring and edge banding alignment verification, these measures work together to maintain precision, consistency, and excellence in manufacturing. By prioritizing quality at every stage of the production process, edge banding cells uphold the highest standards of craftsmanship and customer satisfaction, solidifying their reputation as indispensable tools in modern manufacturing.