Elevating Reliability: Unveiling the Role of TG250 PCBs in High-Reliability and Durable Applications

2023-12-14

Introduction:

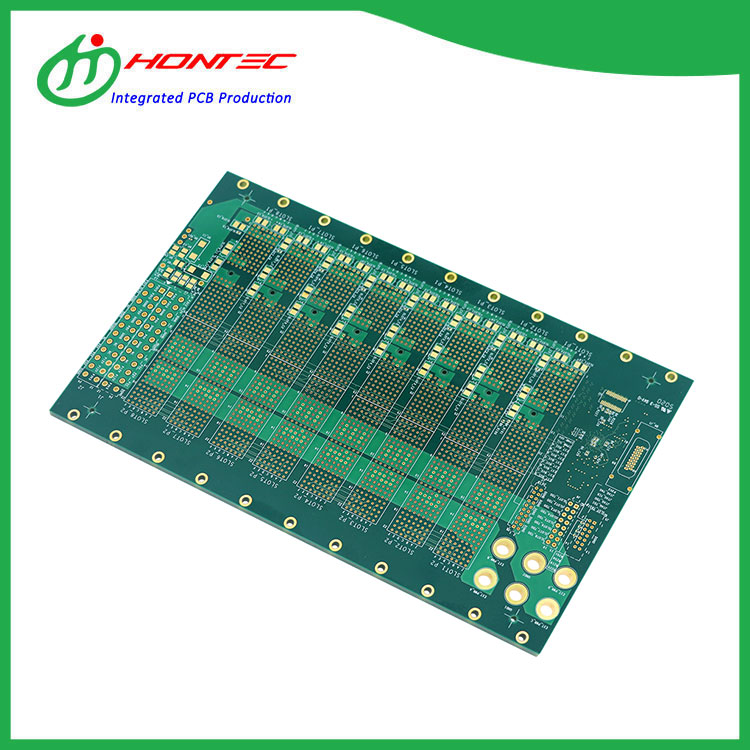

Reliability and durability are non-negotiable factors in many electronic applications, especially those in critical industries like aerospace, automotive, and medical devices. The choice of materials for Printed Circuit Boards (PCBs) becomes paramount in achieving longevity and robust performance. In this blog, we delve into the question: Can TG250 PCBs be used in applications requiring high reliability and durability?

Understanding TG250 Material:

TG250 PCBs are crafted from materials known for their high glass transition temperature (Tg). This characteristic imparts excellent thermal stability and mechanical strength to the PCBs, making them a compelling choice for applications demanding reliability and durability.

Factors Contributing to Reliability:

1. Thermal Stability:

The high Tg of TG250 material ensures that the PCB remains stable even in elevated temperatures. This stability is crucial in applications where temperature fluctuations could compromise the structural integrity of the PCB or impact the functionality of electronic components.

2. Mechanical Strength:

TG250 PCBs exhibit robust mechanical strength, making them resilient to physical stressors such as vibrations, shocks, and mechanical impact. This property is especially vital in applications like automotive electronics, where components may be subjected to harsh environmental conditions.

3. Chemical Resistance:

In certain industries, exposure to chemicals is a common occurrence. TG250 material is often resistant to various chemicals, adding an extra layer of protection against potential damage from exposure to corrosive substances.

Advantages for Durable Applications:

1. Vibration and Shock Resistance:

Industries such as aerospace and automotive require components that can withstand vibrations and shocks. TG250 PCBs, with their high Tg and mechanical strength, provide a reliable solution for applications where these factors are prevalent.

2. Long-Term Stability:

TG250's thermal stability ensures long-term reliability, making it suitable for applications that demand consistent performance over extended periods. This is particularly valuable in critical systems where downtime is not an option.

3. Resistance to Environmental Factors:

TG250 material is often designed to resist environmental factors like moisture and humidity. This resistance contributes to the durability of the PCB, especially in applications where exposure to varying environmental conditions is inevitable.

Considerations for Optimal Performance:

1. Design Considerations:

While TG250 PCBs offer high reliability, optimal performance also depends on the overall PCB design. Designers should consider factors such as proper heat dissipation, efficient component placement, and adherence to design guidelines to maximize the benefits of TG250.

2. Material Compatibility:

TG250 material's compatibility with various manufacturing processes and surface finishes is essential for achieving reliable PCBs. Collaboration with experienced fabricators ensures that the material is used optimally during the manufacturing process.

Conclusion:

TG250 PCBs, with their high Tg, mechanical strength, and resistance to environmental factors, emerge as a dependable choice for applications requiring high reliability and durability. Whether in aerospace, automotive, medical devices, or other critical industries, TG250's properties contribute to the creation of electronic systems that can withstand the rigors of demanding environments. As technology continues to advance, TG250 is likely to remain at the forefront of high-reliability PCB solutions, playing a pivotal role in shaping the future of durable electronic applications.