Are there different types of mesh patterns available for these belts

2023-10-31

There are various types of mesh patterns available for mesh conveyor wire belts, and the choice of mesh pattern depends on the specific application and the requirements of the conveyor system. Different mesh patterns offer unique characteristics and benefits. Here are some common types of mesh patterns:

1. Balanced Weave: This is one of the most common mesh patterns. It features an equal number of warp wires and weft wires per unit length, resulting in a balanced and sturdy mesh structure. Balanced weave is suitable for a wide range of applications, including those requiring a smooth and flat surface.

2. Compound Balanced Weave: In this pattern, a combination of thick and thin wires is used to create a balanced and robust design. The thicker wires provide strength, while the thinner wires offer flexibility. Compound balanced weave is ideal for conveying heavy loads.

3. Chain Weave: Chain weave belts consist of alternating left and right spiral wires, creating a flexible and flat surface. These belts are well-suited for lighter-duty applications and are often used in cooling, drying, and heating processes.

4. Flat-Flex Weave: This weave combines flattened wire spirals, resulting in a more open mesh design. It is used in applications that require increased airflow, drainage, and a non-slip surface. Flat-Flex belts are suitable for cooling, drying, and breading operations.

5. Honeycomb Weave: Honeycomb weave features a hexagonal mesh pattern and is known for its high strength and flat surface. It is often used in applications requiring stability and a smooth, flat surface for product support.

6. Ladder Link: Ladder link belts are constructed with a series of interconnected ladder-like links. These belts are used in heavy-duty applications, especially in industries where products need strong support.

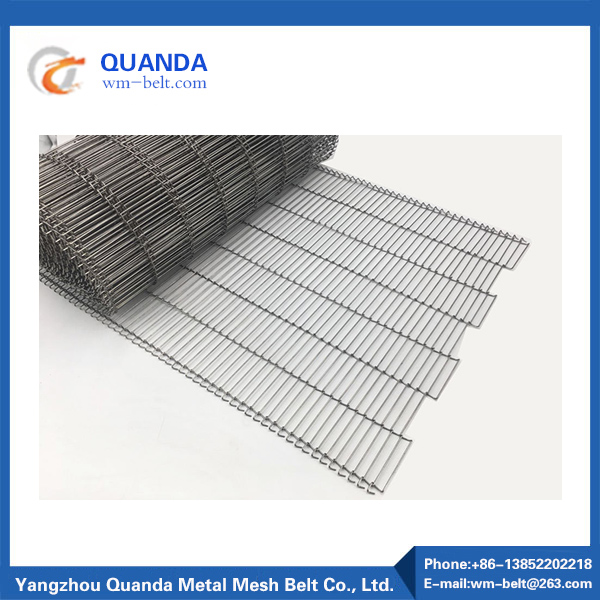

7. Rod Reinforced Weave: This type of mesh pattern incorporates rods that run alongside the spirals, providing additional support and strength to the belt. Rod reinforced belts are used in applications where the belt must support heavy loads or where minimal belt stretch is required.

8. Round Spiral Weave: In this pattern, round wires are woven together to form a spiral structure. Round spiral belts are used in applications that require a smooth and open surface for drying, cooling, or heating.

9. Wire Mesh Belts with Flights or Cleats: In some cases, cleats or flights can be added to the belt, providing an inclined or declined conveying surface and helping to contain products on the belt.

10. Custom Mesh Patterns: Mesh conveyor wire belts can be customized to create unique mesh patterns tailored to specific applications. Customizations may involve variations in wire diameter, spacing, and wire configurations to achieve specific objectives.

The choice of mesh pattern is influenced by the nature of the products being conveyed, the operating environment, load requirements, and the desired surface characteristics. It's important to select the appropriate mesh pattern to optimize the efficiency and performance of the conveyor system in a given application.