A Comprehensive Guide to Thin Wall Tubing: Applications and Benefits

2025-01-23

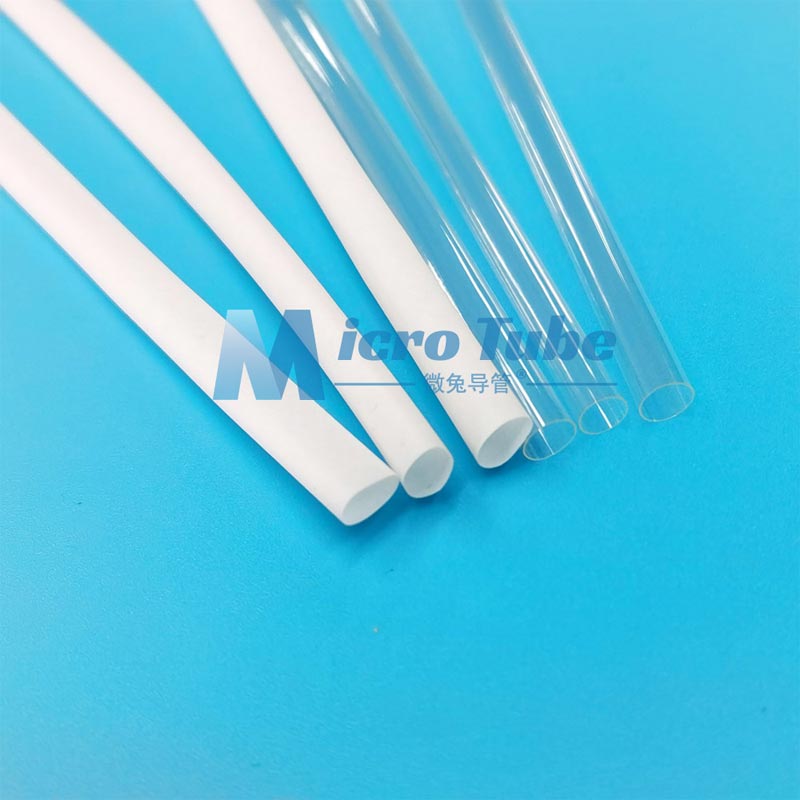

When it comes to precision engineering, versatility, and durability, thin wall tubing is a game-changer. Known for its lightweight design and impressive strength-to-weight ratio, thin wall tubing is widely used across industries like medical, aerospace, automotive, and electronics. In this blog, we’ll explore what makes thin wall tubing unique, its key applications, and the benefits it offers.

What is Thin Wall Tubing?

Thin wall tubing refers to tubes with walls significantly thinner relative to their diameter. They are typically made from materials like stainless steel, aluminum, titanium, or specialized polymers. Despite their thin walls, these tubes maintain high levels of strength, precision, and reliability, making them ideal for high-performance and space-constrained applications.

Common Applications of Thin Wall Tubing

1. Medical Devices

Thin wall tubing is widely used in surgical instruments, catheters, and hypodermic needles. Its biocompatibility and precise dimensions are critical for medical applications.

2. Aerospace and Defense

In the aerospace industry, where weight reduction is a priority, thin wall tubing is used for fuel lines, hydraulic systems, and structural components.

3. Automotive Industry

Thin wall tubing is utilized in exhaust systems, fuel lines, and heat exchangers, contributing to vehicle efficiency and lightweight design.

4. Electronics

For applications requiring miniaturization, such as cable protection or thermal management in electronic devices, thin wall tubing is indispensable.

5. Industrial Applications

Industries use these tubes for fluid transfer, heat exchangers, and other systems requiring high performance and corrosion resistance.

How to Choose the Right Thin Wall Tubing

When selecting thin wall tubing, consider the following factors:

- Material: Choose a material that suits your application, whether it’s for medical-grade stainless steel or lightweight aluminum for aerospace.

- Dimensions: Ensure the tubing dimensions, including inner and outer diameters, align with your requirements.

- Performance Needs: Consider factors like pressure resistance, thermal conductivity, and flexibility.

- Regulations and Standards: For industries like medical or aerospace, ensure the tubing complies with industry standards and certifications.

Thin wall tubing is an indispensable component in many industries, offering unmatched versatility, precision, and durability. Whether you’re in healthcare, aerospace, or manufacturing, understanding its applications and benefits can help you make the most of this innovative material.