A Comprehensive Guide to Edge-Sealed Hollow Boards: Types, Manufacturing, and Selection

2024-11-21

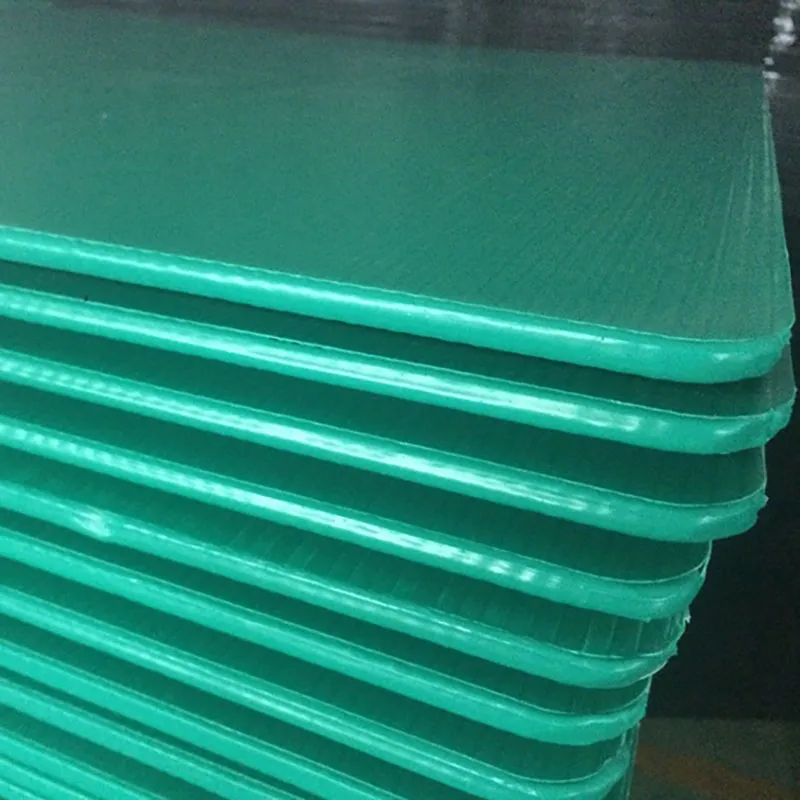

The demand for materials that offer lightweight strength, durability, and environmental protection has driven the development of edge-sealed hollow boards. To maximize their benefits, it’s essential to understand their types, manufacturing processes, and selection criteria. This blog provides a comprehensive guide to edge-sealed hollow boards.

Types of Edge-Sealed Hollow Boards

1. Polypropylene (PP) Hollow Boards:

- Lightweight, flexible, and recyclable.

- Commonly used in packaging and signage.

2. Polycarbonate Hollow Boards:

- High strength and thermal resistance.

- Used in construction and greenhouse panels.

3. Composite Hollow Boards:

- Made by combining plastics with fibers or other materials.

- Ideal for high-performance applications in aerospace and automotive industries.

4. Anti-Static and Conductive Boards:

- Designed to prevent electrostatic discharge.

- Used in electronics packaging and transport.

How Are Edge-Sealed Hollow Boards Manufactured?

1. Core Extrusion:

- The hollow core structure is created through an extrusion process, forming the base of the board.

2. Edge Sealing:

- Edges are sealed using heat, adhesives, or ultrasonic welding to prevent moisture or particle ingress.

3. Surface Coating (Optional):

- Coatings or laminates can be added for specific functionalities, such as UV protection or printing compatibility.

4. Cutting and Customization:

- Boards are cut to required dimensions and customized with features like pre-drilled holes or printed graphics.

Factors to Consider When Selecting Edge-Sealed Hollow Boards

1. Application Needs:

- Define whether the board is for structural support, packaging, or insulation.

2. Material Type:

- Choose materials based on strength, flexibility, and resistance to environmental factors.

3. Size and Thickness:

- Select dimensions that align with load requirements and design constraints.

4. Surface Finish:

- Opt for smooth, textured, or printed surfaces depending on the intended use.

5. Environmental Considerations:

- Consider recyclable options to minimize environmental impact.

Advantages Over Traditional Hollow Boards

1. Enhanced Protection:

- Sealed edges prevent damage and extend product lifespan.

2. Broader Applications:

- Suitable for more demanding environments and industries.

3. Improved Aesthetics:

- Sealed edges provide a cleaner, more professional finish.

Innovations in Edge-Sealed Hollow Board Technology

1. Advanced Sealing Methods:

- Ultrasonic sealing ensures better edge protection and higher durability.

2. Eco-Friendly Materials:

- Development of biodegradable and fully recyclable hollow boards.

3. Custom-Engineered Solutions:

- Boards tailored for specific industries with enhanced properties like fire resistance or anti-static surfaces.

Edge-sealed hollow boards represent a significant advancement in material design, providing lightweight durability and environmental resistance. By understanding their types, manufacturing processes, and applications, you can make informed decisions to leverage their benefits effectively.