Vinyl Adhesive Label Printing

Vinyl adhesive label printing refers to the process of creating custom labels on vinyl material with an adhesive backing. These labels are versatile and widely used for various applications, including product labeling, packaging, branding, identification, and more. Vinyl labels offer durability, res......

Send Inquiry

Product Description

Vinyl adhesive label printing refers to the process of creating custom labels on vinyl material with an adhesive backing. These labels are versatile and widely used for various applications, including product labeling, packaging, branding, identification, and more. Vinyl labels offer durability, resistance to moisture and UV exposure, and the ability to adhere to a wide range of surfaces.

The process of vinyl adhesive label printing typically involves the following steps:

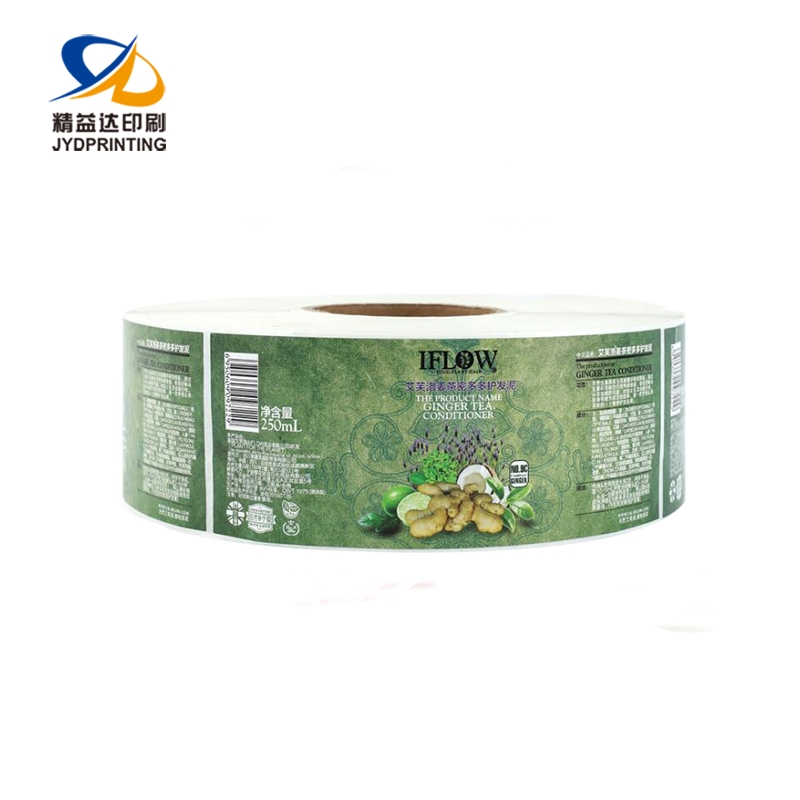

1. Design Creation: Begin by creating the design for your label using graphic design software or specialized label design software. Include the desired text, graphics, logos, colors, and any other elements you want to appear on the label.

2. Material Selection: Choose a vinyl material suitable for your specific application. Vinyl materials come in different finishes, such as gloss, matte, or clear, and may have additional features like high tack adhesives or extra durability for outdoor use.

3. Printing: Once the design and material selection are finalized, the label design is printed onto the vinyl material using a digital or flexographic printing method. Digital printing offers flexibility for smaller print runs and intricate designs, while flexographic printing is more suitable for large volume production.

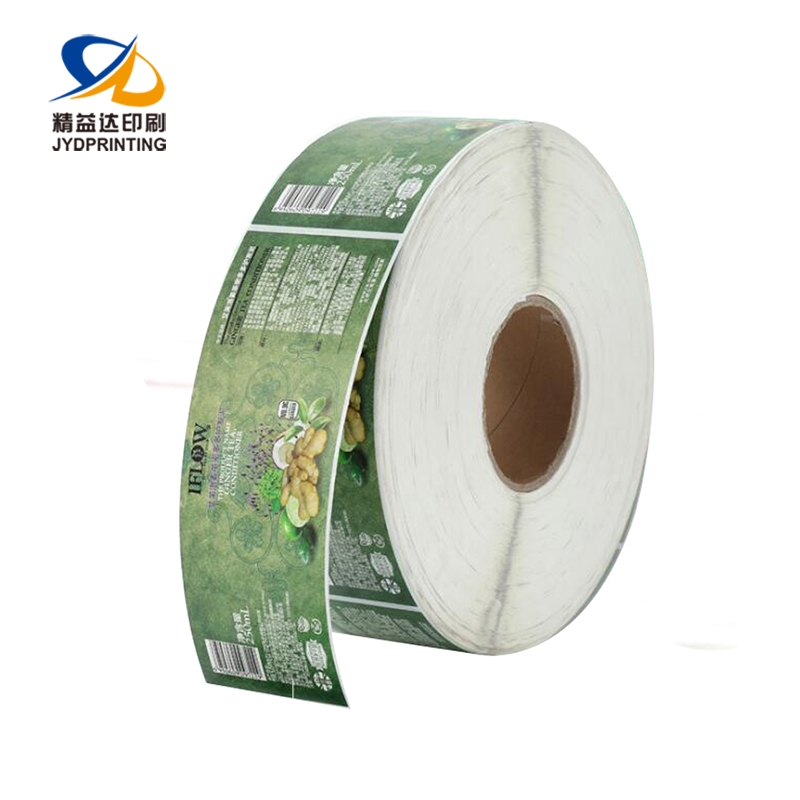

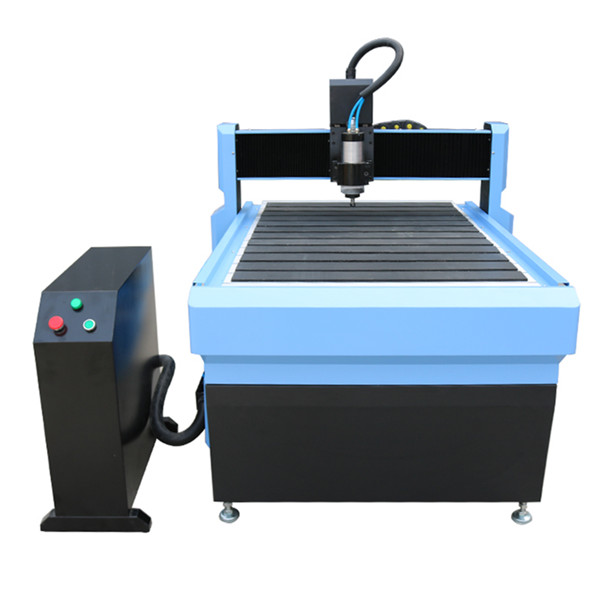

4. Cutting and Finishing: After printing, the vinyl material is typically cut into the desired label shape and size. This can be done using cutting machines or custom dies, depending on the complexity and quantity of labels needed. Additional finishing processes may include laminating for added protection or applying specialty coatings for specific requirements.

5. Adhesive Backing: The vinyl labels are usually equipped with a self-adhesive backing. The adhesive can be permanent or removable, depending on the intended application and label requirements.

6. Application: Once the vinyl labels are ready, they can be applied to the desired surfaces. Ensure that the surface is clean and dry to ensure proper adhesion. Vinyl labels adhere well to various materials, including glass, plastic, metal, and cardboard.

It's important to work with a professional printing service or label manufacturer experienced in vinyl adhesive label printing to ensure high-quality results. They can guide you through the material selection, printing process, and provide options for customization to meet your specific needs.

When communicating with a printing service, be prepared to provide details such as label size, quantity, desired finish, adhesive type, and any specific requirements or preferences you may have. This will help them produce the vinyl adhesive labels that meet your expectations and application requirements.