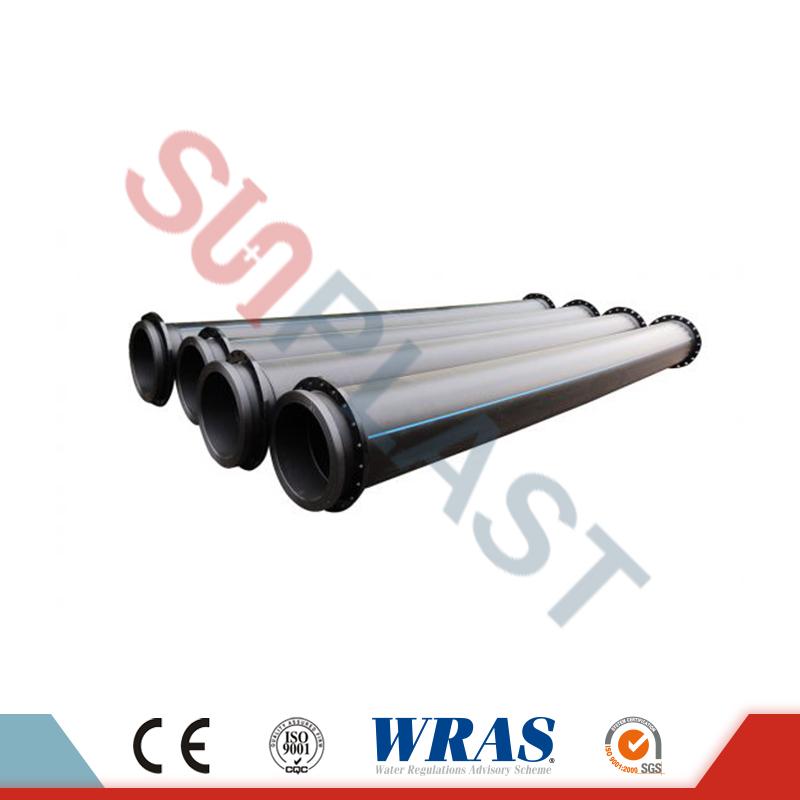

HDPE Dredge Pipe

HDPE (High-Density Polyethylene) dredge pipes are specially designed pipes used in dredging operations to transport sediment, slurry, or other materials from one location to another. These pipes are commonly used in dredging projects to maintain and deepen waterways, extract minerals or resources fr......

Send Inquiry

Product Description

HDPE (High-Density Polyethylene) dredge pipes are specially designed pipes used in dredging operations to transport sediment, slurry, or other materials from one location to another. These pipes are commonly used in dredging projects to maintain and deepen waterways, extract minerals or resources from the seabed, or perform land reclamation.

Here are some key features and considerations of HDPE dredge pipes:

1. Material: HDPE dredge pipes are made from high-density polyethylene, which is a durable and robust thermoplastic material. HDPE is known for its excellent strength, resistance to abrasion, corrosion, and chemicals, as well as its flexibility.

2. Size and Diameter: HDPE dredge pipes are available in various sizes and diameters to suit different dredging requirements. The diameter of the pipe is determined based on the volume of material to be transported and the desired flow rate.

3. Construction and Design: HDPE dredge pipes are typically constructed with a smooth interior surface to minimize flow resistance and enhance material transport. They may feature a flared-end or socket-end design for easy connection and assembly with other pipes or dredging equipment.

4. Floatation and Buoyancy: In some dredging operations, HDPE dredge pipes may incorporate floatation devices or buoyancy modules to provide positive buoyancy and maintain the pipe's position near the water surface. This helps prevent the pipe from sinking and allows for easier installation and retrieval.

5. Corrosion Resistance: HDPE dredge pipes are highly resistant to corrosion, making them suitable for use in marine environments and other corrosive conditions. This resistance ensures the longevity and durability of the pipes, reducing the need for frequent maintenance and replacements.

6. Flexibility and Handling: HDPE dredge pipes are known for their flexibility, which allows them to withstand bending and deformation without compromising their structural integrity. This flexibility makes them easier to handle, transport, and install, particularly in challenging or curved dredging routes.

7. Installation: HDPE dredge pipes can be installed using various methods, including welding, flange connections, or mechanical couplings. The installation technique depends on the specific project requirements and the diameter of the pipes.

8. Environmental Considerations: HDPE dredge pipes are often chosen for their environmentally friendly properties. They are non-toxic, chemically inert, and resistant to biological growth, minimizing the impact on marine ecosystems and water quality.

When selecting HDPE dredge pipes, it is important to consider factors such as the required diameter and length, pressure rating, project specifications, and any relevant industry standards or regulations. It is advisable to consult with experts or manufacturers specializing in dredging equipment to ensure the pipes meet the specific needs of your dredging project.